Roboticsin Industrial Automation

Crimson Technologies offers comprehensive robotics services that empower businesses to embrace the transformative potential of robotics. Our expertise spans various industries, and defense market segments and provides cutting-edge solutions tailored to meet specific needs. Our robotics services encompass everything from concept development and design to implementation and support with optimal cost. We specialize in the Auto Navigation suite comprises the full stack of ROS, SLAM AI, and robotic automation, enabling businesses to enhance productivity, streamline operations, and optimize efficiency. Our team of experienced engineers and technicians is skilled in programming, integration, and customization of robotic systems, ensuring seamless integration with existing processes.

Key Concepts ofRobotics in Industrial Automation

Types of Robots

Industrial robots come in various types, including articulated, SCARA, delta, and collaborative robots, each suited for specific tasks.

Robotics Arms and End-Effectors

Robots are equipped with arms and end-effectors (tools) designed for specific applications.

Sensors and Vision Systems

Robotics utilizes sensors and vision systems for environment perception and interaction.

Programming

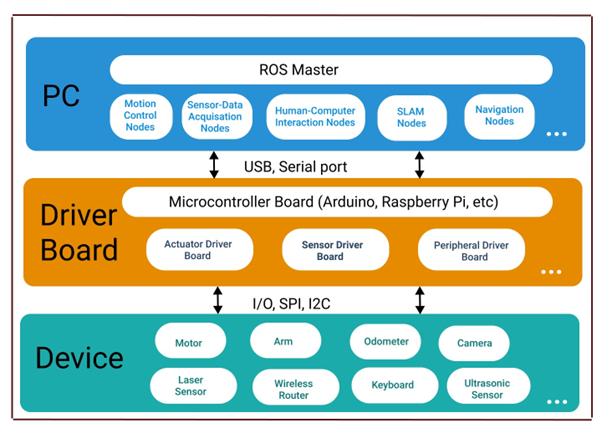

Robots are programmed to perform tasks, and programming languages like Robotic Operating System (ROS) are commonly used.

Autonomous Navigation

Camera Surveillance

Obstacle avoidance (2D and 3D Lidar, Zed camera, Ultrasonic)

Health Status Monitoring

Payload spike emission

Collective Movement of mUGVs with Radio Communication

Waypoint Navigation

Custom Data Link for Command Processing

Benefits ofRobotics

Enhanced Efficiency

Robots perform repetitive tasks with speed and accuracy.

Cost Savings

Automation reduces labor costs and minimizes errors.

Safety

Robots handle dangerous tasks, improving workplace safety.

Scalability

Automation can be easily scaled to meet increasing demands.

Robotics in industrial automation revolutionizes processes by introducing precision, speed, and efficiency. Embracing robotics can lead to increased productivity, cost savings, and enhanced safety in industrial settings.